Product Description

Product Description

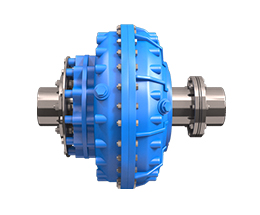

China Wholesale Excavator Flange Coupling Hydraulic Pump Rubber Coupling

| Name | Hydraulic pump coupling |

| Category Group | Rubber Parts |

| Product Name | Flange Coupling |

| Application | Excavator/Wheel loader/Truck |

| Warranty | Half years |

| Used | Excavator Model |

| Stock Condition | In Stock |

Advantage

1.Delivery is fast

2.Sincere service

3.Small order allowed

4.Reasonable price&High quality

More Excavator coupling for your review

1. 8A: SK04V2 PC20

2.16A: PC60 PC40 EX50

3. 16AS: PC40-5 EX55

4. 30A: SK100-5 CHINAMFG MS70B E307

5. 30AS: EX60 HD250 S60-6 SK07

6. 30H: MS110 DH55

7. 40H: EX200-2

8. 50A: E312 E120B HD450 E3118B

9. 50AS: MS120 MS110 MS140 HD512 SH120 LS120 HD450 E120 SH100

10. 50AC 14T : E200B SH200

11. 50AM 16T: MS180-8 E320 E240

12. 50H: EX200-1 EX200-3 EX200-5 HD700 PC200-1 HD800 PC200-3 PC200-5 HD900 E320

SK200 SK220 R210 LS160 LS70 E320B SK200-6 SK200-3 E320C DH220-5 R220-5 R225-7

13. 110H: EX220 EX300-1 EX300-2 EX300-3 SK230 SK220-3 ZAX330 EX350-5 EX330 E325 LS430 EX300

14.140H: HD280 HD1430 PC300-1HD1250 R300 HD300 E330 SK912 SK820 HD1880 DH320-2

15. 160H: LS380 R290 R300-5 SH300A2

16. 28AS: EX120

17. 28A: ZAX200

18. 45H: ZAX200

19. 25H: R60-7 ZAX55

20. 50AM 20T: SH280

We also have stock in these parts:

1. Crank shaft, various sun gear, various planet gears, drive shaft, various travel coupling, transmission gear, speed cut gear, various travel gear discs, travel bearing cover, minor axis, varous drive shaft, vertical shaft

2. Excavator bearing

Products Show:

Recommended Products

Company Profile

Inventory

Exhibitions

Customer Reviews

Packaging & Shipping

Workshop & FAQ

1. How to check the quality of the bulk order?

– We have incoming inspection, control the quality of raw materials, process inspection,to ensure the quality of the production

process, shipping 100% of the full inspection; automatic inspection machine full inspection, and according to customer needs

before the mass production of pre-production samples.

2.How can I pay for the parts?

– We will send you invoice once you confirm the order. We offer T/T Paypal, Western Union, Trade Assurance Service on Alibaba.

3. What is your terms of Delivery?

– EXW. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the maintenance requirements for hydraulic couplings to ensure optimal performance?

Maintaining hydraulic couplings is crucial to ensure their optimal performance and extend their service life. Regular maintenance helps identify potential issues early on and prevents costly breakdowns. Here are the essential maintenance requirements for hydraulic couplings:

- Inspection: Regularly inspect the hydraulic coupling for signs of wear, damage, or leaks. Check for any unusual noises, vibrations, or changes in performance during operation.

- Lubrication: Ensure proper lubrication of the coupling’s moving parts. Use the manufacturer-recommended lubricants and follow the specified intervals for re-lubrication.

- Coupling Alignment: Check and correct the alignment of the driving and driven shafts connected by the coupling. Misalignment can lead to premature wear and reduce coupling efficiency.

- Bolt Tightening: Regularly check and tighten the bolts and fasteners securing the coupling. Loose bolts can lead to coupling slippage and compromised power transmission.

- Cleanliness: Keep the hydraulic coupling and its surrounding area clean from dirt, debris, and contaminants. Clean the coupling during scheduled maintenance to prevent contamination-related issues.

- Temperature and Pressure Checks: Monitor the operating temperature and pressure to ensure they remain within the specified limits for the coupling. Operating beyond the recommended ranges can cause damage and reduce coupling performance.

- Overload Prevention: Avoid exceeding the rated torque capacity of the coupling to prevent overload and potential damage to the coupling or connected equipment.

- Replacement of Worn Parts: Replace any worn or damaged components of the hydraulic coupling promptly. Follow the manufacturer’s guidelines for part replacement and use genuine spare parts when needed.

- Periodic Maintenance: Establish a regular maintenance schedule for the hydraulic coupling based on the operating conditions and manufacturer recommendations. Adhering to this schedule helps identify and address issues before they become severe.

- Expert Inspection: If you encounter any unusual performance issues or suspect coupling problems, consult a hydraulic system expert for a detailed inspection and analysis. They can provide valuable insights and recommendations for maintenance and repairs.

Proper and consistent maintenance of hydraulic couplings is essential to ensure their reliability, efficiency, and safe operation. By following the recommended maintenance practices, you can prolong the life of the hydraulic coupling and optimize the performance of your hydraulic system.

How do hydraulic couplings ensure efficient torque transmission and prevent fluid leaks?

Hydraulic couplings are designed with specific features to ensure efficient torque transmission and prevent fluid leaks, making them vital components in hydraulic systems. These features contribute to the overall performance and reliability of the hydraulic system. Here’s how hydraulic couplings achieve these goals:

- High-Quality Materials: Hydraulic couplings are manufactured using high-quality materials, such as steel, stainless steel, brass, or other durable alloys. These materials offer excellent strength and wear resistance, allowing the couplings to withstand high torque and pressure loads without deforming or leaking.

- Precision Machining: Hydraulic couplings undergo precise machining processes to achieve tight tolerances and smooth surfaces. This ensures proper alignment and mating of coupling components, minimizing energy losses and enhancing torque transmission efficiency.

- Sealing Mechanisms: Hydraulic couplings incorporate various sealing mechanisms to prevent fluid leaks. O-rings, seals, or face seals are common sealing methods used in hydraulic couplings. When the coupling components are connected, the seals create a secure barrier, preventing hydraulic fluid from escaping the system.

- Leak-Free Designs: Modern hydraulic couplings often feature leak-free designs that minimize the risk of fluid leakage during operation. These designs utilize advanced sealing technologies and tight tolerances to ensure a reliable and durable connection, even under high-pressure conditions.

- Threaded Connections: Many hydraulic couplings use threaded connections, such as NPT, BSP, JIC, or SAE threads, to create a secure and leak-resistant joint. Properly tightened threaded connections maintain the integrity of the hydraulic system, reducing the likelihood of leaks.

- Quick-Connect Couplings: Quick-connect hydraulic couplings are designed for rapid and easy connection and disconnection, often without the need for additional tools. These couplings use internal valves and seals to ensure a leak-free connection when engaged and prevent fluid leaks when disengaged.

- Hermetically Sealed Couplings: In specific applications, hermetically sealed hydraulic couplings use magnetic coupling technology to provide a non-contact, leak-free transmission of torque and power. These couplings have no physical contact points, making them suitable for critical environments or systems handling hazardous fluids.

The combination of these design features ensures that hydraulic couplings efficiently transmit torque from one component to another while maintaining a secure and reliable seal to prevent fluid leaks. This is particularly important in hydraulic systems, where fluid leakage can lead to reduced performance, increased maintenance, and potential safety hazards.

Proper selection, installation, and maintenance of hydraulic couplings are crucial to optimize their torque transmission capabilities and prevent fluid leaks. Regular inspections and replacement of worn-out seals or damaged couplings are essential to ensure the continued efficiency and safety of the hydraulic system.

In summary, hydraulic couplings play a crucial role in efficient torque transmission and fluid sealing in hydraulic systems. Their robust construction, precision engineering, and advanced sealing technologies contribute to the overall performance and reliability of hydraulic machinery and equipment.

What are the different types of hydraulic couplings used in various industrial applications?

Hydraulic couplings come in various types and designs to suit different industrial applications. Some of the commonly used types include:

- Jaw Couplings: Jaw couplings are versatile and widely used in industrial machinery. They consist of two hubs with interlocking jaws that transmit torque between the shafts. These couplings provide good misalignment capacity and vibration damping.

- Disc Couplings: Disc couplings use a series of thin, flexible metal discs to transmit torque. They offer high torsional stiffness and can accommodate misalignments. They are commonly found in high-performance applications and precision equipment.

- Fluid Couplings: Fluid couplings use hydraulic fluid to transmit torque. They are suitable for applications requiring smooth start-ups and shock absorption. These couplings are often used in heavy machinery, such as conveyors and crushers.

- Gear Couplings: Gear couplings consist of gear teeth on the hubs that mesh with each other to transmit torque. They offer high torque capacity and can handle misalignments and shock loads. Gear couplings are commonly used in heavy-duty industrial applications.

- Oldham Couplings: Oldham couplings use a sliding disc in the middle to transmit torque. They provide high misalignment capacity and are used in applications where shafts are not in perfect alignment.

- Diaphragm Couplings: Diaphragm couplings use a thin metal diaphragm to transmit torque. They provide high torsional stiffness and can handle high speeds and misalignments. These couplings are used in applications like pumps and compressors.

- Beam Couplings: Beam couplings use helical cuts in a flexible beam to transmit torque. They are lightweight and have good misalignment capacity. Beam couplings are used in precision equipment and motion control applications.

- Universal Joints: While not a traditional hydraulic coupling, universal joints are used in fluid power transmission applications. They provide flexibility in transmitting torque at varying angles and are commonly found in drivetrains and automotive systems.

Each type of hydraulic coupling has its advantages and limitations, making them suitable for specific industrial applications based on factors like torque requirements, misalignment tolerance, and operating conditions. Proper selection and maintenance of hydraulic couplings are essential to ensure efficient power transmission and prolong the life of the machinery.

editor by CX 2024-02-21