Product Description

High quality

Competitive price

Professional services

Some question:

Q1. What kind of products do you produce?

A. CHINAMFG focuses on the production of hydraulic connectors, including quick connectors, hydraulic connectors, high-pressure ball valve assemblies and other products.

Q2. Will you help to print the logo?

A. Yes, we will print logo according to different requirements of customers.

Q3. Can you produce products with my own brand?

A. Yes, we have provided OEM service for 20 years.

Q4. How long does it take for my order to be delivered?

A. It usually takes 5 to 30 days, which usually depends on your order quantity and our stock.

Q5. Can some non-standard parts be customized?

A. Yes, we can process suitable products according to the drawings or samples you provide.

Steel construction, zinc plated with yellow chromate finish. hardened nipples and sleeves and CHINAMFG barstock construction for maximum resistance to damage from hydraulic and mechanical shock.

This Anti -Blowout Nitrile/PTFE bonded seal is designed to prevent blow-out or damage during severe service conditions.

Durable ball-locking mechanism assures reliable connections every time.

A large number of locking balls distributes the work load evenly while providing alignment and swiveling action to reduce hose torque and prolong hose life.

AUTION: These products are not not to be used as swivels.

Rotation under press&re will result in excessive and premature wear.

PT Series couplings employ flush valving when connecting or disconnecting.

This means that the valves are mated together so that only small amounts of fluid can be lost during disconnection or air inclusion during reconnection.

New chrome plating treatment provides advanced anti-rust performance.

PT series conforms to standard of ISO16571.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Are there specialized hydraulic couplings for high-pressure or high-flow applications?

Yes, there are specialized hydraulic couplings designed to meet the demands of high-pressure and high-flow applications. These specialized couplings are engineered to handle the increased loads, pressures, and flow rates typically encountered in industrial settings where heavy-duty equipment and machinery are used. Here are some types of hydraulic couplings commonly used in such applications:

- High-Pressure Hydraulic Couplings: High-pressure hydraulic couplings are constructed with robust materials and advanced sealing technologies to withstand extreme pressure levels. They are commonly used in hydraulic systems that operate at pressures exceeding standard hydraulic system limits. These couplings ensure reliable power transmission and prevent leakage or failure under high-pressure conditions.

- Quick-Disconnect Couplings: Quick-disconnect couplings, also known as quick-release or quick-connect couplings, are designed for rapid and efficient connection and disconnection of hydraulic lines. They are prevalent in high-flow applications where frequent connections and disconnections are necessary, such as in construction equipment, agricultural machinery, and manufacturing processes.

- Multi-Couplings: Multi-couplings allow the simultaneous connection of multiple hydraulic lines with a single motion. These couplings are suitable for applications with complex hydraulic circuits, such as material handling systems and mobile hydraulics. They simplify the connection process and minimize downtime during equipment setup or maintenance.

- High-Flow Hydraulic Couplings: High-flow hydraulic couplings are designed to accommodate large volumetric flow rates in hydraulic systems. They feature larger passageways and flow channels to reduce pressure drop and ensure efficient fluid transfer in applications like heavy machinery, material handling, and large-scale industrial processes.

- Flush Face Couplings: Flush face couplings provide a leak-free connection when connected or disconnected. They are suitable for high-pressure applications where minimizing fluid loss during connection and disconnection is critical for safety and environmental reasons.

- Flat Face Couplings: Flat face couplings are ideal for high-pressure applications where cleanliness and contamination control are essential. Their flat mating surfaces prevent trapping debris during connection, making them suitable for construction equipment, mining machinery, and other rugged applications.

- High-Temperature Hydraulic Couplings: High-temperature hydraulic couplings are designed to operate in extreme temperature environments, such as those encountered in hot industrial processes or near machinery generating significant heat. They use specialized seals and materials that can withstand elevated temperatures without compromising performance.

Specialized hydraulic couplings are engineered to handle the unique challenges posed by high-pressure or high-flow applications, ensuring safe, efficient, and reliable operation in demanding industrial environments. When selecting a hydraulic coupling for such applications, it’s crucial to consider factors like the specific pressure and flow requirements, environmental conditions, compatibility with the hydraulic fluid, and the overall system design to achieve optimal performance and safety.

How do hydraulic couplings ensure efficient torque transmission and prevent fluid leaks?

Hydraulic couplings are designed with specific features to ensure efficient torque transmission and prevent fluid leaks, making them vital components in hydraulic systems. These features contribute to the overall performance and reliability of the hydraulic system. Here’s how hydraulic couplings achieve these goals:

- High-Quality Materials: Hydraulic couplings are manufactured using high-quality materials, such as steel, stainless steel, brass, or other durable alloys. These materials offer excellent strength and wear resistance, allowing the couplings to withstand high torque and pressure loads without deforming or leaking.

- Precision Machining: Hydraulic couplings undergo precise machining processes to achieve tight tolerances and smooth surfaces. This ensures proper alignment and mating of coupling components, minimizing energy losses and enhancing torque transmission efficiency.

- Sealing Mechanisms: Hydraulic couplings incorporate various sealing mechanisms to prevent fluid leaks. O-rings, seals, or face seals are common sealing methods used in hydraulic couplings. When the coupling components are connected, the seals create a secure barrier, preventing hydraulic fluid from escaping the system.

- Leak-Free Designs: Modern hydraulic couplings often feature leak-free designs that minimize the risk of fluid leakage during operation. These designs utilize advanced sealing technologies and tight tolerances to ensure a reliable and durable connection, even under high-pressure conditions.

- Threaded Connections: Many hydraulic couplings use threaded connections, such as NPT, BSP, JIC, or SAE threads, to create a secure and leak-resistant joint. Properly tightened threaded connections maintain the integrity of the hydraulic system, reducing the likelihood of leaks.

- Quick-Connect Couplings: Quick-connect hydraulic couplings are designed for rapid and easy connection and disconnection, often without the need for additional tools. These couplings use internal valves and seals to ensure a leak-free connection when engaged and prevent fluid leaks when disengaged.

- Hermetically Sealed Couplings: In specific applications, hermetically sealed hydraulic couplings use magnetic coupling technology to provide a non-contact, leak-free transmission of torque and power. These couplings have no physical contact points, making them suitable for critical environments or systems handling hazardous fluids.

The combination of these design features ensures that hydraulic couplings efficiently transmit torque from one component to another while maintaining a secure and reliable seal to prevent fluid leaks. This is particularly important in hydraulic systems, where fluid leakage can lead to reduced performance, increased maintenance, and potential safety hazards.

Proper selection, installation, and maintenance of hydraulic couplings are crucial to optimize their torque transmission capabilities and prevent fluid leaks. Regular inspections and replacement of worn-out seals or damaged couplings are essential to ensure the continued efficiency and safety of the hydraulic system.

In summary, hydraulic couplings play a crucial role in efficient torque transmission and fluid sealing in hydraulic systems. Their robust construction, precision engineering, and advanced sealing technologies contribute to the overall performance and reliability of hydraulic machinery and equipment.

Are there specific pressure and temperature limits for different hydraulic coupling designs?

Yes, different hydraulic coupling designs have specific pressure and temperature limits, and these limits can vary based on the coupling type and construction materials. Here are some general considerations regarding pressure and temperature limits for common hydraulic coupling designs:

- Jaw Couplings: Jaw couplings typically have a pressure rating ranging from 1000 psi to 5000 psi (6.9 MPa to 34.5 MPa) and can handle temperatures from -20°C to 120°C (-4°F to 248°F). These couplings are suitable for various industrial applications with moderate pressure and temperature requirements.

- Disc Couplings: Disc couplings offer higher pressure and temperature capabilities compared to jaw couplings. Their pressure rating can range from 2000 psi to 6000 psi (13.8 MPa to 41.4 MPa), and they can handle temperatures between -50°C to 150°C (-58°F to 302°F). These couplings are commonly used in high-performance and precision equipment.

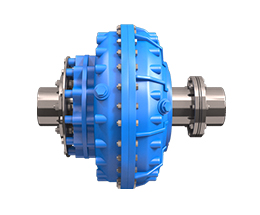

- Fluid Couplings: Fluid couplings are suitable for applications requiring smooth start-ups and shock absorption. Their pressure limits can range from 150 psi to 3000 psi (1.03 MPa to 20.7 MPa), and they can handle temperatures from -40°C to 150°C (-40°F to 302°F). These couplings are often used in heavy machinery, such as conveyors and crushers.

- Gear Couplings: Gear couplings have a higher pressure rating, typically ranging from 2500 psi to 8000 psi (17.2 MPa to 55.2 MPa), and can handle temperatures from -20°C to 150°C (-4°F to 302°F). These couplings are commonly used in heavy-duty industrial applications with high torque requirements.

- Oldham Couplings: Oldham couplings have pressure limits ranging from 500 psi to 3000 psi (3.4 MPa to 20.7 MPa) and can handle temperatures between -30°C to 100°C (-22°F to 212°F). They are suitable for applications where shafts are not in perfect alignment.

- Diaphragm Couplings: Diaphragm couplings offer high pressure and temperature capabilities. Their pressure rating can range from 3000 psi to 10000 psi (20.7 MPa to 68.9 MPa), and they can handle temperatures from -50°C to 200°C (-58°F to 392°F). These couplings are commonly used in high-speed and high-temperature applications like pumps and compressors.

- Beam Couplings: Beam couplings typically have a pressure rating ranging from 1000 psi to 4000 psi (6.9 MPa to 27.6 MPa) and can handle temperatures between -40°C to 150°C (-40°F to 302°F). They are commonly used in precision equipment and motion control applications.

It’s essential to consult the manufacturer’s specifications and guidelines for each specific hydraulic coupling design to ensure it is suitable for the intended application’s pressure and temperature requirements. Using a coupling within its specified limits ensures safe and reliable operation and maximizes the performance and lifespan of the hydraulic system.

editor by CX 2024-04-08