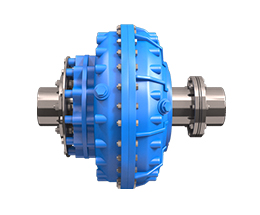

Product Description

SongQiao LSQ-FF Series couplings are widely used in the public utility market where hydraulic oil spillage can constitute a serious safety hazard, particularly in overhead bucket hoists that are used for maintenance of high-voltage power transmission lines.These couplings are also used for quick change of hydraulic Tools in construction, railway maintenance and mining industries. The ease of cleaning makes them ideal for use in these types of hostile environments.

New valve design. it can resistance damage from high flow and the pressure of impulse that providing advanced performance.

Sleeve locking mechanism is engaged by rotating sleeve after connection. It prevents accidental disconnection when, The coupling is dragged along the ground.

Sleeve mechanism is designed to prevent dirt from entering the internal the internal mechanism and thus causing faulty operation when connecting or disconnecting. The sleeve covers the retaining ring and also incorporates a dust seal in the spring area.

Steel construction, zinc plated with yellow chromate finish. hardened nipples and sleeves and CHINAMFG barstock construction for maximum resistance to damage from hydraulic and mechanical shock.

This Anti Blowout Nitrile/PTFE bonded seal is designed to prevent blow-out or damage during severe service conditions.

Durable ball-locking mechanism assures reliable connections ,every time. A large number of locking balls distributes the work load evenly while providing alignment and swiveling action to reduce hose torque and prolong hose life. CAUTION: These products are not not to be used as swivels. Rotation under pressure will result in excessive and premature wear.

LSQ-FF Series couplings employ flush valving when connecting or disconnecting. This means that the valves are mated together so that only small amounts of fluid can be lost during disconnection or air inclusion during reconnection.

New chrome plating treatment provides advanced anti-rust performance.

LSQ-FF series conforms to standard of ISO16571.

Compatible with CHINAMFG FE Series,FFSeries,STUCCHIA8008 Series, AEROQUIP FD89 Series and HANSENQA2900 Series.

| ISO | PART NO | LS | D | HEX1 | A | T |

| 6.3 | LSQ-FF-02SF | 58.2 | 28 | 20 | 14 | G1/4 NPT1/4 |

| 10 | LSQ-FF-03SF | 68.2 | 32 | 24 | 14 | G3/8 NPT3/8 |

| 10 | LSQ-FF-03SF | 72.2 | 32 | 27 | 18 | G1/2 NPT1/2 |

| 12.5 | LSQ-FF-04SF | 75 | 38 | 32 | 18 | G1/2 NPT1/2 |

| 12.5 | LSQ-FF-04SF | 79 | 38 | 36 | 22 | G3/4 NPT3/4 |

| 16 | LSQ-FF-06SF | 80 | 42 | 36 | 22 | G3/4 NPT3/4 |

| 19 | LSQ-FF-08SF | 99.8 | 48 | 41 | 22 | G3/4 NPT3/4 |

| 19 | LSQ-FF-08SF | 99.8 | 48 | 41 | 23.5 | G1 NPT1 |

| 25 | LSQ-FF-10SF | 111.5 | 56 | 55 | 24 | G1-1/4 NPT1-1/4 |

| – | LSQ-FF-12SF | 150 | 79.5 | 65 | 30 | G1-1/2 NPT1-1/2 |

| – | LSQ-FF-16SF | 167 | 98.5 | 85 | 31 | G2 NPT2 |

| ISO | PART NO | LP | d | C | HEX2 | A | T |

| 6.3 | LSQ-FF-02PF | 49.2 | 16.1 | 15.2 | 20 | 14 | G1/4 NPT1/4 |

| 10 | LSQ-FF-03PF | 55.8 | 19.7 | 19.5 | 24 | 14 | G3/8 NPT3/8 |

| 10 | LSQ-FF-03PF | 59.8 | 19.7 | 19.5 | 27 | 18 | G1/2 NPT1/2 |

| 12.5 | LSQ-FF-04PF | 72 | 24.5 | 21.6 | 32 | 18 | G1/2 NPT1/2 |

| 12.5 | LSQ-FF-04PF | 76 | 24.5 | 21.6 | 36 | 22 | G3/4 NPT3/4 |

| 16 | LSQ-FF-06PF | 75.5 | 27 | 21.6 | 36 | 22 | G3/4 NPT3/4 |

| 19 | LSQ-FF-08PF | 93.8 | 30 | 29 | 41 | 22 | G3/4 NPT3/4 |

| 19 | LSQ-FF-08PF | 93.8 | 30 | 29 | 41 | 23.5 | G1 NPT1 |

| 25 | LSQ-FF-10PF | 90 | 36 | 34 | 55 | 24 | G1-1/4 NPT1-1/4 |

| – | LSQ-FF-12PF | 112 | 57 | 38 | 65 | 30 | G1-1/2 NPT1-1/2 |

| – | LSQ-FF-16PF | 123.9 | 73 | 40.5 | 75 | 31 | G2 NPT2 |

| ISO | PART NO | L | D | HEX1 | HEX2 | T |

| 6.3 | LSQ-FF-02 | 96.2 | 28 | 20 | 20 | G1/4 NPT1/4 |

| 10 | LSQ-FF-03 | 108.4 | 32 | 24 | 24 | G3/8 NPT3/8 |

| 10 | LSQ-FF-03 | 116.4 | 32 | 27 | 27 | G1/2 NPT1/2 |

| 12.5 | LSQ-FF-04 | 129.3 | 38 | 32 | 32 | G1/2 NPT1/2 |

| 12.5 | LSQ-FF-04 | 137.3 | 38 | 36 | 36 | G3/4 NPT3/4 |

| 16 | LSQ-FF-06 | 138 | 42 | 36 | 36 | G3/4 NPT3/4 |

| 19 | LSQ-FF-08 | 172.1 | 48 | 41 | 41 | G3/4 NPT3/4 |

| 19 | LSQ-FF-08 | 172.1 | 48 | 41 | 41 | G1 NPT1 |

| 25 | LSQ-FF-10 | 178 | 56 | 55 | 55 | G1-1/4 NPT1-1/4 |

| – | LSQ-FF-12 | 233.4 | 79.5 | 65 | 65 | G1-1/2 NPT1-1/2 |

| – | LSQ-FF-16 | 251.7 | 98.5 | 85 | 75 | G2 NPT2 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can hydraulic couplings be used in applications involving corrosive or aggressive fluids?

Yes, hydraulic couplings can be used in applications involving corrosive or aggressive fluids, but the choice of materials and design considerations is critical to ensure compatibility and long-term performance. Corrosive fluids, such as acids, alkalis, and certain chemicals, can pose significant challenges to hydraulic systems. Here are some key factors to consider when using hydraulic couplings in such applications:

- Material Selection: Choose hydraulic couplings made from materials that are resistant to the specific corrosive fluid being handled. Stainless steel, certain alloys, and corrosion-resistant coatings are common choices for couplings in corrosive environments.

- Sealing Solutions: Ensure that the couplings have effective sealing solutions to prevent fluid leakage. High-quality seals and gaskets that are compatible with the corrosive fluid are essential to maintain system integrity.

- Chemical Compatibility: Thoroughly assess the chemical compatibility between the hydraulic fluid and the coupling materials. Consider the fluid’s temperature, concentration, and potential reactions with the coupling components.

- Special Coatings: In some cases, using hydraulic couplings with specialized coatings or treatments can enhance their resistance to corrosion and aggressive fluids.

- Regular Inspection and Maintenance: Implement a stringent inspection and maintenance schedule to monitor the condition of the hydraulic couplings and detect any signs of corrosion or degradation. Promptly replace any damaged or worn couplings to prevent fluid leaks and system failure.

- Fluid Contamination: Corrosive fluids can lead to the formation of contaminants in the hydraulic system. Implement effective filtration and contamination control measures to prevent particle buildup and system damage.

- Operating Conditions: Consider the temperature, pressure, and flow conditions of the system, as these factors can impact the corrosion resistance of the couplings and the overall system performance.

While hydraulic couplings can be used in corrosive or aggressive fluid applications, it is essential to consult with coupling manufacturers or fluid system experts to ensure proper material selection and system design. They can provide guidance on selecting the most suitable hydraulic couplings and recommend additional measures to protect the system from the adverse effects of corrosive fluids.

By employing the right materials, adopting proper maintenance practices, and taking the necessary precautions, hydraulic couplings can effectively function in applications involving corrosive or aggressive fluids, providing reliable and safe fluid power transmission.

How do hydraulic couplings ensure efficient torque transmission and prevent fluid leaks?

Hydraulic couplings are designed with specific features to ensure efficient torque transmission and prevent fluid leaks, making them vital components in hydraulic systems. These features contribute to the overall performance and reliability of the hydraulic system. Here’s how hydraulic couplings achieve these goals:

- High-Quality Materials: Hydraulic couplings are manufactured using high-quality materials, such as steel, stainless steel, brass, or other durable alloys. These materials offer excellent strength and wear resistance, allowing the couplings to withstand high torque and pressure loads without deforming or leaking.

- Precision Machining: Hydraulic couplings undergo precise machining processes to achieve tight tolerances and smooth surfaces. This ensures proper alignment and mating of coupling components, minimizing energy losses and enhancing torque transmission efficiency.

- Sealing Mechanisms: Hydraulic couplings incorporate various sealing mechanisms to prevent fluid leaks. O-rings, seals, or face seals are common sealing methods used in hydraulic couplings. When the coupling components are connected, the seals create a secure barrier, preventing hydraulic fluid from escaping the system.

- Leak-Free Designs: Modern hydraulic couplings often feature leak-free designs that minimize the risk of fluid leakage during operation. These designs utilize advanced sealing technologies and tight tolerances to ensure a reliable and durable connection, even under high-pressure conditions.

- Threaded Connections: Many hydraulic couplings use threaded connections, such as NPT, BSP, JIC, or SAE threads, to create a secure and leak-resistant joint. Properly tightened threaded connections maintain the integrity of the hydraulic system, reducing the likelihood of leaks.

- Quick-Connect Couplings: Quick-connect hydraulic couplings are designed for rapid and easy connection and disconnection, often without the need for additional tools. These couplings use internal valves and seals to ensure a leak-free connection when engaged and prevent fluid leaks when disengaged.

- Hermetically Sealed Couplings: In specific applications, hermetically sealed hydraulic couplings use magnetic coupling technology to provide a non-contact, leak-free transmission of torque and power. These couplings have no physical contact points, making them suitable for critical environments or systems handling hazardous fluids.

The combination of these design features ensures that hydraulic couplings efficiently transmit torque from one component to another while maintaining a secure and reliable seal to prevent fluid leaks. This is particularly important in hydraulic systems, where fluid leakage can lead to reduced performance, increased maintenance, and potential safety hazards.

Proper selection, installation, and maintenance of hydraulic couplings are crucial to optimize their torque transmission capabilities and prevent fluid leaks. Regular inspections and replacement of worn-out seals or damaged couplings are essential to ensure the continued efficiency and safety of the hydraulic system.

In summary, hydraulic couplings play a crucial role in efficient torque transmission and fluid sealing in hydraulic systems. Their robust construction, precision engineering, and advanced sealing technologies contribute to the overall performance and reliability of hydraulic machinery and equipment.

Can you explain the working principle of a hydraulic coupling and its advantages over other coupling types?

A hydraulic coupling operates based on the principle of hydraulic fluid transmission to transfer power from one shaft to another. It consists of two main parts: the input (driving) element and the output (driven) element, both of which have specially designed vanes or blades submerged in hydraulic fluid.

When the input element rotates, it creates a flow of hydraulic fluid around the vanes. The fluid flow generates pressure on the output element, causing it to start rotating. This pressure difference between the input and output elements facilitates the transfer of torque and power from the driving shaft to the driven shaft.

The working principle of a hydraulic coupling allows it to accommodate misalignments and torsional vibrations. It effectively isolates shock loads, provides overload protection, and dampens vibrations, making it ideal for various industrial applications.

Advantages of hydraulic couplings over other coupling types include:

- Misalignment Tolerance: Hydraulic couplings can handle significant shaft misalignments, reducing wear and tear on the system and prolonging the life of the components. Other coupling types may have limitations in this regard.

- Vibration Damping: Hydraulic couplings can effectively dampen vibrations, preventing damage to connected equipment and promoting smoother operation. This advantage is especially critical in precision machinery and applications where vibrations can affect accuracy and performance.

- Overload Protection: Hydraulic couplings offer built-in overload protection. When the torque exceeds a certain threshold, the fluid coupling slips or disengages, preventing damage to the system and its components. Other coupling types may not have this automatic overload protection.

- Smooth Start-up: Hydraulic couplings provide gradual power transmission during start-up, which helps minimize shock and stress on the system. This feature is beneficial for systems with heavy loads or delicate components.

- Quiet Operation: Due to their vibration-damping properties, hydraulic couplings contribute to quieter operation, reducing noise levels in the machinery compared to some other coupling types.

- Wide Range of Applications: Hydraulic couplings are suitable for a wide range of industrial applications, including heavy machinery, mining equipment, conveyors, pumps, and more. Their adaptability and robust performance make them a popular choice in various industries.

While hydraulic couplings offer many advantages, the selection of the appropriate coupling type ultimately depends on the specific requirements of the application, such as torque, speed, misalignment, and environmental conditions. Properly choosing and maintaining the coupling can significantly improve the efficiency, reliability, and overall performance of fluid power transmission systems in industrial settings.

editor by CX 2024-04-08