Product Description

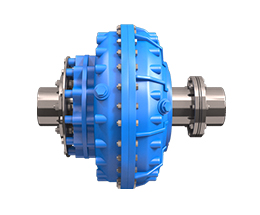

Excavator Parts Coupling Main Hydraulic Pump Coupling Assy DL550-5

Basic information:

| Type | Coupling |

| Trademark | YNF/Y&F |

| MOQ | No limited |

| Structure | AS/A/Bowex/Gear |

| Used For | Excavator |

| Sales type | Retail, Wholesale |

| Material | Natural Rubber |

| Advantage | Flexible, Lower Noise |

| Condition | OEM/Original |

Product show as below:

About us:

specialized in:

couplings, rubber mounts, gera parts, hydraulic seals and seal kits for hydraulic hammers, rock breakers, hydraulic excavators,wheel loaders, and JCB badkhoe loaders.

And, Our company also supply:

Engine parts, hydraulic piston pump and hydraulic travel motor, Swing motor assembly and hydraulic component parts, electric parts, etc. Hydraulic hammer breaker parts with piston, cylinder, chisel, through bolt, side bolt, top bush, front head bushing,accumlator, valve, etc.

We always try our best for all our customers and make it better and better. Welcome!

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How do hydraulic couplings contribute to reducing vibrations and noise in hydraulic systems?

Hydraulic couplings play a crucial role in reducing vibrations and noise in hydraulic systems, providing several mechanisms that help dampen and absorb these unwanted effects. Here’s how hydraulic couplings contribute to vibration and noise reduction:

- Torsional Flexibility: Hydraulic couplings are designed with torsional flexibility, allowing them to twist and absorb torsional vibrations that may occur during operation. As the fluid flows through the coupling, it acts as a damping medium, attenuating vibrations and minimizing their transmission to the rest of the system.

- Vibration Isolation: The inherent flexibility of hydraulic couplings helps isolate vibrations between the driving and driven components of the hydraulic system. This isolation prevents vibrations from propagating through the system, reducing the overall vibration levels and promoting smoother operation.

- Shock Absorption: In systems subject to sudden changes in load or pressure, hydraulic couplings can act as shock absorbers. They cushion the impact of these shock loads, preventing them from reverberating through the system and causing noise or damage to sensitive components.

- Damping Characteristics: Hydraulic couplings, especially those utilizing a hydraulic fluid medium, exhibit excellent damping characteristics. The fluid dissipates energy by converting kinetic energy into heat energy, effectively reducing the system’s resonant vibrations and noise.

- Smooth Power Transmission: Hydraulic couplings provide smooth power transmission between the driving and driven elements. The absence of jerks or sudden changes in torque helps in minimizing vibrations and noise generation, leading to quieter operation.

- Compensation for Misalignments: Hydraulic couplings can compensate for certain misalignments between the shafts they connect. By accommodating misalignments, the couplings reduce the stress on the system components, mitigating vibrations that might arise from misalignment-induced forces.

- Elimination of Metal-to-Metal Contact: In certain couplings, the use of elastomeric or flexible elements eliminates direct metal-to-metal contact between the driving and driven shafts. This reduces transmission of vibrations and noise, resulting in a quieter system.

By incorporating these vibration and noise-reducing features, hydraulic couplings enhance the overall performance and longevity of hydraulic systems. They contribute to a more pleasant working environment by minimizing noise levels and reducing the risk of fatigue failure caused by excessive vibrations. Additionally, reduced vibrations help prevent premature wear and extend the lifespan of system components, ultimately leading to cost savings and improved efficiency in industrial applications.

Are hydraulic couplings suitable for use in hydraulic cylinders or pumps?

Yes, hydraulic couplings are commonly used in hydraulic cylinders and pumps, playing a crucial role in connecting various components within hydraulic systems. Hydraulic cylinders and pumps are essential components in hydraulic systems, responsible for generating and controlling fluid power to perform mechanical work.

Hydraulic cylinders are actuators that convert fluid pressure into linear motion, producing force and movement. They are widely used in various applications, such as construction machinery, manufacturing equipment, agricultural machinery, and automotive systems.

Hydraulic pumps, on the other hand, are responsible for generating the fluid flow and pressure required to operate hydraulic systems. They provide the driving force that enables hydraulic cylinders and other actuators to perform their intended tasks.

Hydraulic couplings are used in hydraulic cylinders and pumps to connect hoses, tubes, and other hydraulic components. They ensure a secure and leak-free connection, allowing hydraulic fluid to flow between different parts of the system. Some common coupling types used in hydraulic cylinders and pumps include:

- JIC Fittings: JIC (Joint Industry Council) fittings, which have a 37-degree flare angle, are commonly used in high-pressure hydraulic systems, including hydraulic cylinders and pumps. They provide reliable metal-to-metal sealing and are easy to assemble and disassemble.

- ORFS Fittings: ORFS (O-Ring Face Seal) fittings are widely used in high-pressure hydraulic applications. They provide a robust and leak-free connection through an O-ring seal in the face of the fitting.

- NPT Fittings: NPT (National Pipe Thread) fittings, with their tapered threads, are commonly used in lower-pressure hydraulic systems, providing a reliable seal with the use of thread sealants like Teflon tape.

- BSP Fittings: BSP (British Standard Pipe) fittings, available in parallel (BSPP) and tapered (BSPT) threads, are widely used in European hydraulic systems.

Properly selected and installed hydraulic couplings ensure the integrity of the hydraulic system, allowing efficient and reliable power transmission between hydraulic cylinders, pumps, valves, and other components. When using hydraulic couplings in hydraulic cylinders and pumps, it’s essential to consider factors such as the required pressure rating, flow capacity, material compatibility, and environmental conditions to ensure optimal performance and safety.

In summary, hydraulic couplings are essential components in hydraulic systems, making them well-suited for use in hydraulic cylinders and pumps, where they facilitate fluid flow and help maintain the integrity of the overall hydraulic system.

What is a hydraulic coupling, and how does it function in fluid power transmission?

A hydraulic coupling is a mechanical device used in fluid power systems to transmit power from one shaft to another, often at different angles or distances. It facilitates the transfer of hydraulic energy from a prime mover, such as an electric motor or an internal combustion engine, to various hydraulic components, such as pumps, actuators, and cylinders.

The main function of a hydraulic coupling is to transmit rotational motion and power while accommodating misalignments and torsional vibrations. It acts as a link between the driving and driven shafts, ensuring that the hydraulic system operates smoothly and efficiently.

Hydraulic couplings operate based on the principle of hydraulic fluid transmission. The coupling consists of two main parts, the input (driving) and output (driven) elements, both of which have specially designed vanes or blades. These vanes are submerged in hydraulic fluid.

When the input element rotates, it creates a flow of hydraulic fluid around the vanes, which in turn generates pressure on the output element. The pressure difference between the two elements causes the output element to start rotating, effectively transmitting power from the input shaft to the output shaft.

Hydraulic couplings are advantageous in various applications due to their ability to:

- Isolate Shock Loads: They can isolate and dampen shock loads and torsional vibrations, protecting sensitive components from sudden jolts and improving overall system performance.

- Accommodate Misalignment: Hydraulic couplings can accommodate misalignment between the input and output shafts, reducing wear and tear on the system and extending the lifespan of the components.

- Provide Overload Protection: They offer overload protection by slipping or disengaging when the torque exceeds a certain threshold, preventing damage to the system and its components.

- Start-Up Assistance: Hydraulic couplings can provide smooth start-up assistance, gradually transmitting power as the fluid builds up pressure, minimizing shock and stress during system startup.

- Reduce Noise and Vibration: By dampening vibrations and shock loads, hydraulic couplings contribute to quieter and smoother operation of fluid power systems.

Overall, hydraulic couplings play a critical role in fluid power transmission, ensuring efficient power transfer, protecting components from shocks and vibrations, and enhancing the overall performance and reliability of hydraulic systems in various industrial and mobile applications.

editor by CX 2024-05-06