Product Description

Product Description

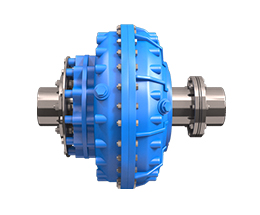

FCL flexible coupling is widely used,owing to its advantages:compact designing,easy installation,convenient maintenance,small size and light weight.As long as the relative displacement between shafts is kept within the specified tolerance,coupling will operate the best function and have a longer working life.

Size available from:90,100,112,125,140,160,180,200,224,250,280,315,355,400,450,560,630

FCL flexible coupling is widely used for its compact design, easy installation, convenient maintenance, small size and light weight.

1. A flexible structure that is made through combining a flange with a coupling bolt.

2. Easy to attach.

3. Easy to replace the bush by just removing the coupling bolt, which makes maintenance and preservation easy.

4. Absorbs misalignment such as eccentricity and declination, and absorbs screw vibrations to prevent noise.

5. Does not transmit the thrust load.

6. Material could be customized.

Detailed Photos

Product Parameters

Packaging & Shipping

| Package | Standard suitable package / Pallet or container. Polybag inside export carton outside, blister and Tape and reel package available. If customers have specific requirements for the packaging, we will gladly accommodate. |

| Shipping |

10-20working days ofter payment receipt comfirmed (based on actual quantity). Professional goods shipping forward. |

Company Profile

FAQ

Q: Are you trading company or manufacturer?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit. To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can hydraulic couplings be used in applications involving corrosive or aggressive fluids?

Yes, hydraulic couplings can be used in applications involving corrosive or aggressive fluids, but the choice of materials and design considerations is critical to ensure compatibility and long-term performance. Corrosive fluids, such as acids, alkalis, and certain chemicals, can pose significant challenges to hydraulic systems. Here are some key factors to consider when using hydraulic couplings in such applications:

- Material Selection: Choose hydraulic couplings made from materials that are resistant to the specific corrosive fluid being handled. Stainless steel, certain alloys, and corrosion-resistant coatings are common choices for couplings in corrosive environments.

- Sealing Solutions: Ensure that the couplings have effective sealing solutions to prevent fluid leakage. High-quality seals and gaskets that are compatible with the corrosive fluid are essential to maintain system integrity.

- Chemical Compatibility: Thoroughly assess the chemical compatibility between the hydraulic fluid and the coupling materials. Consider the fluid’s temperature, concentration, and potential reactions with the coupling components.

- Special Coatings: In some cases, using hydraulic couplings with specialized coatings or treatments can enhance their resistance to corrosion and aggressive fluids.

- Regular Inspection and Maintenance: Implement a stringent inspection and maintenance schedule to monitor the condition of the hydraulic couplings and detect any signs of corrosion or degradation. Promptly replace any damaged or worn couplings to prevent fluid leaks and system failure.

- Fluid Contamination: Corrosive fluids can lead to the formation of contaminants in the hydraulic system. Implement effective filtration and contamination control measures to prevent particle buildup and system damage.

- Operating Conditions: Consider the temperature, pressure, and flow conditions of the system, as these factors can impact the corrosion resistance of the couplings and the overall system performance.

While hydraulic couplings can be used in corrosive or aggressive fluid applications, it is essential to consult with coupling manufacturers or fluid system experts to ensure proper material selection and system design. They can provide guidance on selecting the most suitable hydraulic couplings and recommend additional measures to protect the system from the adverse effects of corrosive fluids.

By employing the right materials, adopting proper maintenance practices, and taking the necessary precautions, hydraulic couplings can effectively function in applications involving corrosive or aggressive fluids, providing reliable and safe fluid power transmission.

How do hydraulic couplings ensure efficient torque transmission and prevent fluid leaks?

Hydraulic couplings are designed with specific features to ensure efficient torque transmission and prevent fluid leaks, making them vital components in hydraulic systems. These features contribute to the overall performance and reliability of the hydraulic system. Here’s how hydraulic couplings achieve these goals:

- High-Quality Materials: Hydraulic couplings are manufactured using high-quality materials, such as steel, stainless steel, brass, or other durable alloys. These materials offer excellent strength and wear resistance, allowing the couplings to withstand high torque and pressure loads without deforming or leaking.

- Precision Machining: Hydraulic couplings undergo precise machining processes to achieve tight tolerances and smooth surfaces. This ensures proper alignment and mating of coupling components, minimizing energy losses and enhancing torque transmission efficiency.

- Sealing Mechanisms: Hydraulic couplings incorporate various sealing mechanisms to prevent fluid leaks. O-rings, seals, or face seals are common sealing methods used in hydraulic couplings. When the coupling components are connected, the seals create a secure barrier, preventing hydraulic fluid from escaping the system.

- Leak-Free Designs: Modern hydraulic couplings often feature leak-free designs that minimize the risk of fluid leakage during operation. These designs utilize advanced sealing technologies and tight tolerances to ensure a reliable and durable connection, even under high-pressure conditions.

- Threaded Connections: Many hydraulic couplings use threaded connections, such as NPT, BSP, JIC, or SAE threads, to create a secure and leak-resistant joint. Properly tightened threaded connections maintain the integrity of the hydraulic system, reducing the likelihood of leaks.

- Quick-Connect Couplings: Quick-connect hydraulic couplings are designed for rapid and easy connection and disconnection, often without the need for additional tools. These couplings use internal valves and seals to ensure a leak-free connection when engaged and prevent fluid leaks when disengaged.

- Hermetically Sealed Couplings: In specific applications, hermetically sealed hydraulic couplings use magnetic coupling technology to provide a non-contact, leak-free transmission of torque and power. These couplings have no physical contact points, making them suitable for critical environments or systems handling hazardous fluids.

The combination of these design features ensures that hydraulic couplings efficiently transmit torque from one component to another while maintaining a secure and reliable seal to prevent fluid leaks. This is particularly important in hydraulic systems, where fluid leakage can lead to reduced performance, increased maintenance, and potential safety hazards.

Proper selection, installation, and maintenance of hydraulic couplings are crucial to optimize their torque transmission capabilities and prevent fluid leaks. Regular inspections and replacement of worn-out seals or damaged couplings are essential to ensure the continued efficiency and safety of the hydraulic system.

In summary, hydraulic couplings play a crucial role in efficient torque transmission and fluid sealing in hydraulic systems. Their robust construction, precision engineering, and advanced sealing technologies contribute to the overall performance and reliability of hydraulic machinery and equipment.

Are there specific pressure and temperature limits for different hydraulic coupling designs?

Yes, different hydraulic coupling designs have specific pressure and temperature limits, and these limits can vary based on the coupling type and construction materials. Here are some general considerations regarding pressure and temperature limits for common hydraulic coupling designs:

- Jaw Couplings: Jaw couplings typically have a pressure rating ranging from 1000 psi to 5000 psi (6.9 MPa to 34.5 MPa) and can handle temperatures from -20°C to 120°C (-4°F to 248°F). These couplings are suitable for various industrial applications with moderate pressure and temperature requirements.

- Disc Couplings: Disc couplings offer higher pressure and temperature capabilities compared to jaw couplings. Their pressure rating can range from 2000 psi to 6000 psi (13.8 MPa to 41.4 MPa), and they can handle temperatures between -50°C to 150°C (-58°F to 302°F). These couplings are commonly used in high-performance and precision equipment.

- Fluid Couplings: Fluid couplings are suitable for applications requiring smooth start-ups and shock absorption. Their pressure limits can range from 150 psi to 3000 psi (1.03 MPa to 20.7 MPa), and they can handle temperatures from -40°C to 150°C (-40°F to 302°F). These couplings are often used in heavy machinery, such as conveyors and crushers.

- Gear Couplings: Gear couplings have a higher pressure rating, typically ranging from 2500 psi to 8000 psi (17.2 MPa to 55.2 MPa), and can handle temperatures from -20°C to 150°C (-4°F to 302°F). These couplings are commonly used in heavy-duty industrial applications with high torque requirements.

- Oldham Couplings: Oldham couplings have pressure limits ranging from 500 psi to 3000 psi (3.4 MPa to 20.7 MPa) and can handle temperatures between -30°C to 100°C (-22°F to 212°F). They are suitable for applications where shafts are not in perfect alignment.

- Diaphragm Couplings: Diaphragm couplings offer high pressure and temperature capabilities. Their pressure rating can range from 3000 psi to 10000 psi (20.7 MPa to 68.9 MPa), and they can handle temperatures from -50°C to 200°C (-58°F to 392°F). These couplings are commonly used in high-speed and high-temperature applications like pumps and compressors.

- Beam Couplings: Beam couplings typically have a pressure rating ranging from 1000 psi to 4000 psi (6.9 MPa to 27.6 MPa) and can handle temperatures between -40°C to 150°C (-40°F to 302°F). They are commonly used in precision equipment and motion control applications.

It’s essential to consult the manufacturer’s specifications and guidelines for each specific hydraulic coupling design to ensure it is suitable for the intended application’s pressure and temperature requirements. Using a coupling within its specified limits ensures safe and reliable operation and maximizes the performance and lifespan of the hydraulic system.

editor by CX 2024-04-11